2011 Rover Design Overview

2011 Mars Rover Design

A formal design report has been created by the team which gives a detailed overview of all technical aspects of th 2011 OSU Mars Rover. To download this report click the image at left.

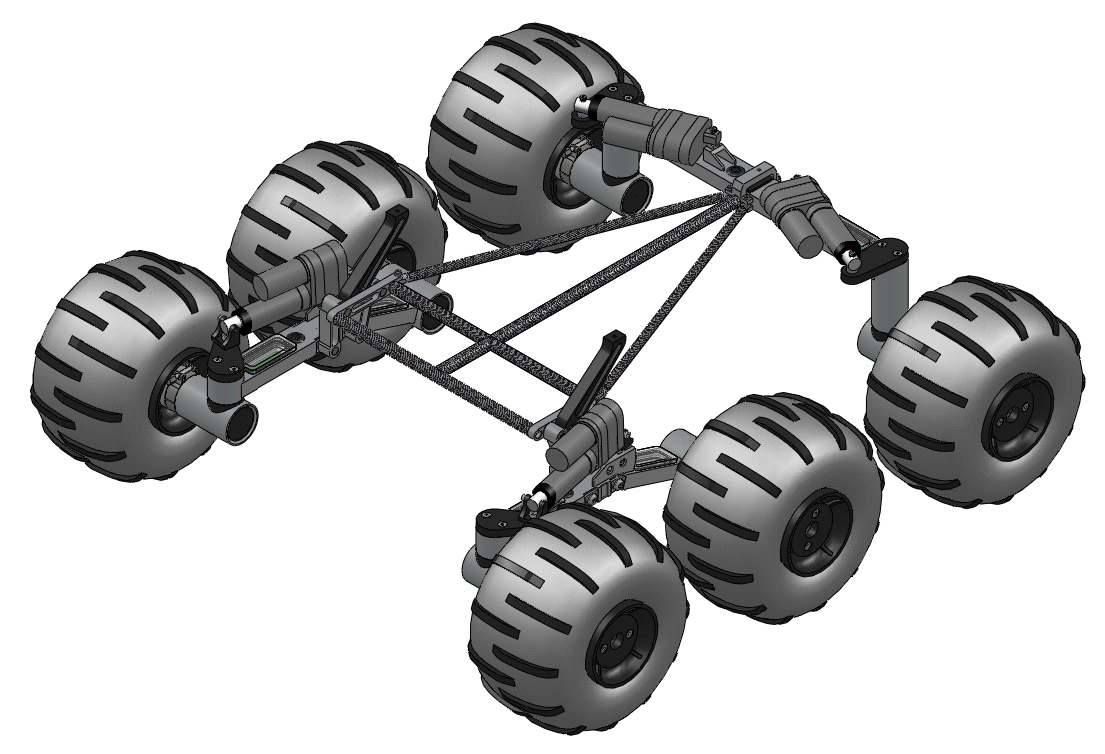

Chassis

This year's OSU Mars Rover is very similar in the overall design with some very important changes. The rover will still include a six wheel independent drive system. The suspension system is still a rocker, rocker system that was so successful last year. The main steering system still includes skid steer and zero radius turning.

The main goal of the chassis design team was to shed weight, and allocate it to different aspects of the rover design. The first move in slimming up the rover was a redesign of the main frame of the chassis. This redesign included using alternative materials than used in the 2010 design and utilizing some different structural components. This year's chassis consists of a carbon fiber/aluminum composite with a truss-style structure for the rear suspension system. Another main change this year is a redesign of the front rocker suspension. To address some problems with wheelies that occurred last year, we have switched from a single point hinge to a four bar linkage system. These will allow us to tune the suspension to have the same performance as last year while eliminating the possibility of the rover popping a wheelie.

In order make the rover more agile over difficult terrain, a set of actuators can change the orientation of the front and rear wheels, rotating them about a vertical axis (a swivel inside the bogie) so that all wheel axes intercept the same point at the center of the rover.

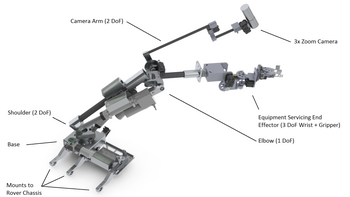

Robotic Arm

This year's Rover Arm will have more functionality than years past. The changes in the 2011 URC rules have increased the scope of tasks that the arm can perform.

OSU's approach to designing a robotic arm to accomplish these variety of functions is with a base 3 Degree of Freedom spherical coordinate system with 3 removable end effectors for each specific task. Each end effector can be removed quickly by one person, by hand while the system is powered arm or off. In addition to all of this is a camera arm extending from the elbow of the main arm which will provide us a mobile viewing platform in tandem with the primary rover camera. When the arm is not in use it will fold into a stowed position lowering its center of mass and restraining itself from movement so that the rover can traverse complex terrain with zero concern for the safety of the arm.

The arm is mounted to the front of the arm with clamps that allow for quick and simple removal of the arm from the rover. The structure of the arm is a filament wound carbon fiber tube glued into aluminum joints and driven by electric linear actuators. The astronaut assistance task requires the arm to lift a package weighting up to 13.2 lbs (6 kg). The packages will be carried by a 'luggage rack' located on the top of the rover's electrical housing. For loading and unloading packages the arm will be equipped with the 'Astro Gripper' featuring a hooked gripper to grip a lifting ring secured to the package. An animation of this process is available on our vidoes page.

The arm will be equipped with a shovel scoop for the sample return task. The arm will work much like that of a backhoe for acquiring soil and rock samples and holding them for the return journey.

Electrical System

This year's electrical system design aimed to improve upon strong points and fix critical design issues in last year's design. Similar to last year, most of our main control hardware is situated inside the electronics bay, connected to various satellite modules including motor drivers, arm and tripod controllers, cameras, sensors, and antennas.

Major design overhauls led to the use of a central controller based around Atmel ATXmega microcontrollers that communicates with satellite modules over a reliable RS-485 bus architecture. Navigation and orientation feedback systems make use of a Garmin GPS receiver and two 3-axis accelerometers. Control modules for our video systems, motors, and arm have been custom designed by Oregon State students.

Last year, the use of an analog video transmission scheme limited us to viewing only one of our cameras at a time and it often faced signal integrity issues when passing behind terrain. A new multi-channel digital video and audio system will increase overall system reliability and allow for greater situational awareness during complex tasks involving arm operation.

Communication to the base station this year is carried out over a 900MHz packet serial link and digital video streams are carried via a high power 802.11N network. This new all digital system simplifies setup and reduces the need for large antenna towers that proved problematic during competition setup last year.

Software

Driving User Interface

This year's rover software system is a complete overhaul from previous years. The on-board computer has been replaced with an AVR XMEGA microcontroller. This XMEGA communicates with the satellite modules spread around the rover, forwarding commands sent from the base station and sending status reports back to base. These status reports include information on rover temperature, module failures, battery health, and more.

In addition to the rover's control software, a cust user interface, run on a laptop at the base station is being developed. This user interface provides the basic functionality necessary to drive the rover, as well as more advanced interfaces to assist with competition tasks. These include a map with satellite imagery, topographical information, GPS position, and points of interest, and a screen dedicated to recording science information on each site visited.

Science

The science team has been researching biological soil crusts and other soil types found in the Utah desert. Soil crusts are communities of varying extremophiles that thrive in near-barren soil under the extreme conditions of the desert climate. These biological crusts are mostly composed of cyanobacteria, a bacteria that photosynthesizes and is believed to be the link in the evolution of microorganisms to plants. Soil crusts are essential to the desert ecosystem in preventing erosion and encouraging the growth of other flora. Being able to recognize the characteristics of these crusts and their habitats is essential for sample return task.

Along with researching soil crusts, the science team has been researching the equipment to analyze the crusts. Currently, we have a portable spectrometer. Extremophiles reflect a certain spectrum of light, which we can detect with the spectrometer. We are looking into using a conductivity probe on both the rover and at the base station for analyzing on-site soil and soil samples. Electrical conductivity reveals moisture content, salinity, and organic material in soil. Conditions we are taking into consideration include robustness, conductivity range and accuracy, and means of calibration.

Soil Incubator

In order to test the science equipment, we built a incubator in attempt to cultivate desert extremophiles. We obtained several soil types similar to those found in the Utah desert from OSU's Crop and Soils department. Hopefully the provided moisture, UV light, and high temperature will stimulate the organisms within the soil to grow. If after repeated testing over the next several weeks show that there is no biological activity occurring, we will purchase the strain of extremophile cyanobacteria most commonly found in soil crusts and inoculate the soil samples in the incubator. Although a soil crust most likely won't form, the presence of organic material should be enough to detect and analyze.